The Travel Box

One thing I wanted before I 'adopted' a hawk into my family was to have a safe,

and hopefully comfortable, travel box for it that fitted into my car properly.

I used to be a Range Rover owner and in that it would have been just too easy

but I have updated and gone to a super efficient hybrid. My newer, lower,

streamlined ultra economical thing really doesn't have any nice flat places to

put something large and boxy. However I did notice that it had the standard

'Isofix' baby seat fixing points on the rear seats. I reasoned that I must be

able to do something creative with them for my new baby.

One thing I wanted before I 'adopted' a hawk into my family was to have a safe,

and hopefully comfortable, travel box for it that fitted into my car properly.

I used to be a Range Rover owner and in that it would have been just too easy

but I have updated and gone to a super efficient hybrid. My newer, lower,

streamlined ultra economical thing really doesn't have any nice flat places to

put something large and boxy. However I did notice that it had the standard

'Isofix' baby seat fixing points on the rear seats. I reasoned that I must be

able to do something creative with them for my new baby.

Let's start with the target hawk box as I'm definitely not making that. Steve

at Sussex Falconry said nice things about the products from

Falconry

Fabrications and he used them himself. Getting the right size was obviously

the critical thing to be both hawk and car friendly so this one is rated as big

enough for a female Harris Hawk by being 63.5cm tall, 43cm wide and 51.5cm deep

(Coke can for scale). A few checks revealed that if it faced the car door it

wouldn't actually much of a problem. However it had to be securely fastened and

kept upright. That would be a bit more of an engineering challenge.

The general rule that I have developed over the years is that if you want to

build a complex mechanism that you're not planning on selling then you first

try and find somebody else who has already done it well and use theirs. With

this in mind I bought a used child's car seat with all the testing approvals on

EBay (a Maxi-Cosi Cabriofix Car Seat with Isofix Base). Then I gutted it like a rat

in the hawk food tray for its Isofix mechanism. The two yellow ends are the

lock-in claws that engage into the Isofix mounting points in the car giving a

child safety approved level of solidity and the release button is on the end of

the tube reaching forward with a nice colour change indicator in the button to

reassure you it is fully engaged. I kept the release mechanism pretty much 'as

is' because that put the control right where it was easy to get at and check it

was engaged and not something behind the box to try and check.

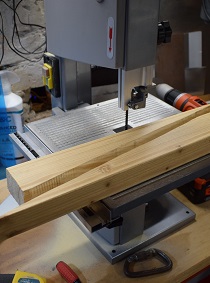

The next real snag was attaching the box to the mechanism. This part is

normally surrounded by its plastic case which is pretty solid but I wanted to

bolt it to a piece of plywood. I went for wood rather than metal as welding up

plates would make the end result too heavy to handle. There were two nice

tapped bolt-holes in the rear cross arm but that is loose in the fore-and-aft

direction so I wanted some proper bolts but this is box section and too thin to

tap. The solution I settled for was M6 bolts with a 15mm hole in the other side

of the box section to get a slender socket through and nylock nuts. Not ideal

but it provided enough rigidity.

I removed the seat's leg that supported the button end of the mechanism even

though it would have added even more stability as it could easily become a

serious 'in the way' problem installing and removing things. Sadly in the sort

of accident that that was designed to protect against the hawk, loose in its

box, will probably get thrown about badly but getting a hawk to wear a seatbelt

is just not going to happen. For normal 'social and domestic' travel we just

need to keep things stable.

The next stage was to make a level 'table' for the box to sit on. This has to

be the full size of the box as its bottom is recessed and it sits on its edges.

The slope of the seat is taken out with some tapered wooden blocks between the

baseplate and the table. These parts are liberally screwed together.

To provide something to clamp the box to the table I fitted two 40mm x 3mm

stainless steel bars to it that are set into the recessed base with the rest of

the gap filled by some 7mm Ali plates so the bars are flush with the bottom of

the box to minimise any stress. There are further stainless steel strips inside

the box to act as a full width 'washer' to distribute the load and it uses M6

stainless bolts sawn off flush with their nylocks to minimise the things that

stick into the box. The bars project about 5cms at the sides and on the left

hand side, towards the rear of the car, engage in fabricated metal slots that

provide positive location. What you do is place the box on the table, push it

away from you so it locates against the back stop then push it sideways,

towards the rear of the car, to run it up against the side stop. This slides

the bars in their slots pretty painlessly.

On the other side, towards the front of the car, the attachments have to stay

out of the way while the box is being slid about so I put the fixings on hinges

so they swing away over the front and when they come back up they clamp in

place with a pair of Zoot pip pin fasteners from the Hang Gliding toolbox.

These delightful things have balls that stick out near the tip of their pin end

that vanish inside when you push the button on top. They go right through the

wood and engage in the stainless steel of the hinge below sandwiching the bar

and the table.

In use you had to be careful. Those bars originally stuck out like the mythical

swords on Boadicea's chariot and it was a squeeze getting it through the door

without scalping the upholstery or the paintwork. It was never going to go in

with a hawk inside but, once installed, the box door opened fully so the

passenger can mount and dismount at will. I had to resort to the angle grinder

to round the ends of the bars into nice, safe semi-circles.

In use you had to be careful. Those bars originally stuck out like the mythical

swords on Boadicea's chariot and it was a squeeze getting it through the door

without scalping the upholstery or the paintwork. It was never going to go in

with a hawk inside but, once installed, the box door opened fully so the

passenger can mount and dismount at will. I had to resort to the angle grinder

to round the ends of the bars into nice, safe semi-circles.

As you can probably tell I'm rather pleased with the way it came out. Deciding

on the details of the design and sourcing the parts was probably more

complicated than the actual execution, well provided you gloss over the angst

of getting nice countersinks in stainless steel. However it is worth pointing

out that all this messing about put another 75% on the price of the

box.

Oh and yes, as observant people have pointed out, it is a Mercedes E300 so not

actually the best choice for putting a big case into but, as you can see, it

does have just enough headroom. The Falconry Fabrications box seems well

designed to keep all the mess inside and my woodwork is protected by a couple

of coats of marine varnish. Frankly the hawk makes less mess in my car than my

wellies.

Back to main falconry page.

by Nigel Hewitt

One thing I wanted before I 'adopted' a hawk into my family was to have a safe,

and hopefully comfortable, travel box for it that fitted into my car properly.

I used to be a Range Rover owner and in that it would have been just too easy

but I have updated and gone to a super efficient hybrid. My newer, lower,

streamlined ultra economical thing really doesn't have any nice flat places to

put something large and boxy. However I did notice that it had the standard

'Isofix' baby seat fixing points on the rear seats. I reasoned that I must be

able to do something creative with them for my new baby.

One thing I wanted before I 'adopted' a hawk into my family was to have a safe,

and hopefully comfortable, travel box for it that fitted into my car properly.

I used to be a Range Rover owner and in that it would have been just too easy

but I have updated and gone to a super efficient hybrid. My newer, lower,

streamlined ultra economical thing really doesn't have any nice flat places to

put something large and boxy. However I did notice that it had the standard

'Isofix' baby seat fixing points on the rear seats. I reasoned that I must be

able to do something creative with them for my new baby.

In use you had to be careful. Those bars originally stuck out like the mythical

swords on Boadicea's chariot and it was a squeeze getting it through the door

without scalping the upholstery or the paintwork. It was never going to go in

with a hawk inside but, once installed, the box door opened fully so the

passenger can mount and dismount at will. I had to resort to the angle grinder

to round the ends of the bars into nice, safe semi-circles.

In use you had to be careful. Those bars originally stuck out like the mythical

swords on Boadicea's chariot and it was a squeeze getting it through the door

without scalping the upholstery or the paintwork. It was never going to go in

with a hawk inside but, once installed, the box door opened fully so the

passenger can mount and dismount at will. I had to resort to the angle grinder

to round the ends of the bars into nice, safe semi-circles.