Range Rover P38 Electronic Air Suspension

Range Rover P38 Electronic Air Suspension

OK. I admit it. After two and a half years of messing about with the Air

Suspension on my 1996 Range Rover 4.6 HSE I had had a serious sense of humour

failure. I can't complain about the main agent as they had long since

ceased to charge me for the work on the EAS but even plaintive phone calls from

them to the factory was just resulting in bits being changed and no fix that

lasted.

OK. I admit it. After two and a half years of messing about with the Air

Suspension on my 1996 Range Rover 4.6 HSE I had had a serious sense of humour

failure. I can't complain about the main agent as they had long since

ceased to charge me for the work on the EAS but even plaintive phone calls from

them to the factory was just resulting in bits being changed and no fix that

lasted.

So what was happening? I would drive for a while with all the abilities to

change the ride height you would expect from a car that promises serious

off-road abilities and was over £60K when new but after a while all the

lights on the suspension controls would come on and adjustment would be no

longer available. Then, some times a few weeks later, some times just a few

miles, the computer would totally loose the plot, open the dump valves and drop

me onto the bump stops and display the dreaded SLOW:35 MPH

MAX message.

After a couple of limp homes like this, one from Derby to Brighton, and then

discovering that when the main dealer plugged in his Test Book and reset

things it all worked well again with no sensible reported error I started to

get annoyed.

I purchased a kit on EBay to fit T-connectors into the air suspension lines so

you could blow them up manually. Now I suspect that when people are selling

kits to fix a fault the problem is widespread so I am more surprised there

wasn't a factory fix. Anyhow with the kit fitted, a handy scuba cylinder of

compressed air in the boot and a scuba drysuit feed stuffed in a cheap garage

air filler I could pull the power relay, manually blow the system back up

and get home at 70mph like a civilised person. I had to do this from North

Wales once and I did a trip to Falmouth and back towing a 6.5 meter dive club

boat entirely on scuba power.

I purchased a kit on EBay to fit T-connectors into the air suspension lines so

you could blow them up manually. Now I suspect that when people are selling

kits to fix a fault the problem is widespread so I am more surprised there

wasn't a factory fix. Anyhow with the kit fitted, a handy scuba cylinder of

compressed air in the boot and a scuba drysuit feed stuffed in a cheap garage

air filler I could pull the power relay, manually blow the system back up

and get home at 70mph like a civilised person. I had to do this from North

Wales once and I did a trip to Falmouth and back towing a 6.5 meter dive club

boat entirely on scuba power.

This, however, is not a fix but a bodge. For a start I still don't have control

to run the height up and down to load and unload my elderly mother at the

supermarket nor all my scuba gear at the Marina. Plus there is the annoyance

factor of having a multi-feature trip computer that can't display anything

because the space is taken by warning me the EAS is on the blink.

Once upon a time the Land Rover seemed to embody the very essence of get

there and back come hell or high water so something that panics, puts up

its hands in horror and bleats for a main dealer to pat it on the head seems

wrong. It wasn't even trying to reset or report what went wrong. What was it

running? Microsoft EAS? It threw a Blue Screen of Death and just wanted

to be rebooted? I didn't feel I could even sell the mess with a clear

conscience and, anyway when it worked it was just what I wanted, so I needed a

fix.

This is the story of the fix.

Step one was the purchase of a spare ANR4499 Suspension Height Control Unit via

EBay. It wasn't new and when I ran it in the car it worked for a while and then

did just the same this the other one did so I felt assured it wasn't the

computer directly, it was just the unhelpful software loaded into the thing.

Well I'm an Electronic Engineer specialising in embedded computer systems. This

is what I do for a living. I can fix this and I can fix it properly.

The case is pop-riveted together but that's hardly a problem. The first

disappointment was a CPU with the code inside and a part number that implied it

was a semi-custom system. OK so no quick reblow of an EPROM this time. This

is going to be open heart surgery. Run up the hot-air solder gun, yes I do have

full surface mount rework equipment at home, and out came the Central

Processor.

An assessment of the wiring diagrams for the car give me a feel for the number

and type of inputs and outputs in use so I selected a Arizona Microchip PIC

18F4550 CPU to replace things with. I like the Microchip kit and I have the

compilers to work on it so for a one-off it that an easy choice. This

particular chip has the added advantage that I can fit a USB interface and read

and write data and even reprogram the whole core with new microcode via the USB

line. This would mean that software tweaks could just be a matter of sitting in

the car with the lap-top plugged into it and getting the micro-code

just so.

The rest of the spec of the 18F4550 is 32K of program memory, 48MHz clock (the

original ran at 4MHz), 2K of internal RAM and 256 bytes of EEROM for all those

calibration constants and the all important error reports. A2D converters,

pulse rate capture ports, serial ports, timers and lots of I/O pins. There is a

430 page datasheet downloadable from the Arizona website if you want it and it

only costs about a fiver. I did wonder about using the surface mount version

since I wanted to do a PCB for reliability but decided that as I had a

programming jig in DIL for the Arizona range I might as well take the easy

route rather than the pretty one.

Ok here are the scans of the two sides of the PCB after I removed the metal

frame that acts as a heat-sink for the power devices.

Top and Bottom and

here they are again with the component numbers I use in the following

discussion: Top and

Bottom. Please notice that these are my

component numbers and contradict the few that are marked. Also all the

semi-conductors are marked U something because in SMT it's hard to tell diodes

from transistors etc. At least with these diagrams I could work my way round

the PCB and try to understand what was going on.

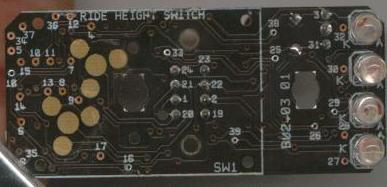

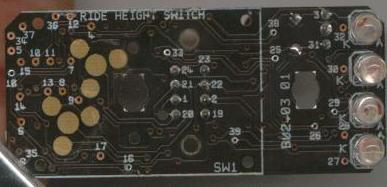

OK snag number one. The little Ride Height Selector Switch with the lights on

only has two wires for four lights so there is some encoding going on here.

Back to EBay and buy a switch for a couple of quid and destroy it.

OK snag number one. The little Ride Height Selector Switch with the lights on

only has two wires for four lights so there is some encoding going on here.

Back to EBay and buy a switch for a couple of quid and destroy it.

It has two ICs inside. One is a dual pulse generator and the other is an eight

bit shift register. At first sight it clocks in four data bits on a rising edge

and first bit in is the lowest LED and the final bit is the highest one.

Interestingly the highest LED, denoting Boulder Strewn Riverbed mode has

a wire back to the Body Electrical Control Module for some reason.

However, just because only 4 bits are used here does not force there to not be

more bits as the two wires, data and clock, are also connected to the BECM

directly. The BECM does not apparently drive the switch as with no power relay

in the switch lights come up randomly and never change.

One half of the pulse generator is used to delay the clock 120μS so both

data and clock can be set simultaneously and the data is given time to settle

before being sampled and the other half is used to prevent the display being

updated while the data is shifting so the lights don't flicker (a 37mS period).

A quick look at the system as it starts with the EAS unpowered shows it running

normally for about a second and then the error lights come on and the 35 mph

message displays. I'd guess the new lamp code is sent every half a second or so

and no message is interpreted as no EAS.

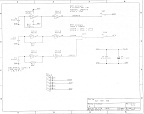

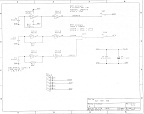

OK. I won't bore you with the internal details of the circuit of the EAS ECU

mainly because I can't be bothered to redraw my scrappy sketches onto the cad

system but here is the pin out for the connector on the

ECU. I traced the circuitry and mapped the signals onto the PCB which gave

me the connection points by name. All the logic

signals are referenced down for a CPU running on 5 volts and the analogue

inputs are buffered and amplified similarly. Nothing is muxed. Nothing seems to

require special handling except the Ride Height Switch.

OK. I won't bore you with the internal details of the circuit of the EAS ECU

mainly because I can't be bothered to redraw my scrappy sketches onto the cad

system but here is the pin out for the connector on the

ECU. I traced the circuitry and mapped the signals onto the PCB which gave

me the connection points by name. All the logic

signals are referenced down for a CPU running on 5 volts and the analogue

inputs are buffered and amplified similarly. Nothing is muxed. Nothing seems to

require special handling except the Ride Height Switch.

Right now this wants fitting to the 18F4550 CPU with the minimum of fuss.

Right now this wants fitting to the 18F4550 CPU with the minimum of fuss.

The planned items were:

Make the In-Circuit programming work so I don't need the USB. This will

save me pulling the CPU out if I send something really silly down the wire.

Connect the engine and road speed signals to the Capture/Compare module as they

look like pulse trains.

Use the on chip analogue to digital converter as 10 bits gives us resolution to

thousandths of max range. Nobody needs to set the ride height to one tenth of a

millimetre so it must be enough.

Use the supplied USB reprogram module so keep the special switch for the

reprogramming mode and do not put anything on the 'lights' it flashes.

Do a full high speed USB connection.

Put the 'datalink' stuff to the 'test book' plug on the built in serial port

as, even if I'm not planning to connect anything to it, I might want too one

day and all the stuff I hear implies it is a serial port.

Here's my plan for a 40 pin DIL cpu and the circuit

diagram for the CPU board.

Right so the next

problem is to reconstruct it so it can be reinstalled and maintained. In my

book this does not involve pop-rivets.

Right so the next

problem is to reconstruct it so it can be reinstalled and maintained. In my

book this does not involve pop-rivets.

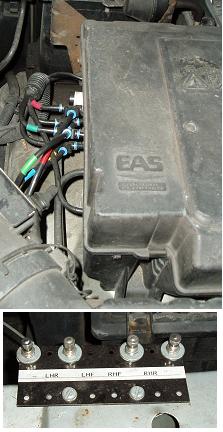

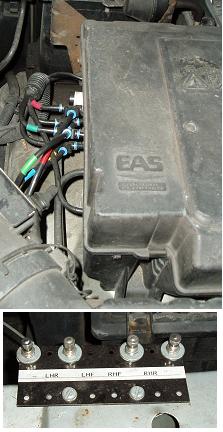

The picture shows the installed position under the passenger seat where the EAS

ECU is centre left underneath a gearbox ECU. In this view the Power Delay

relay (the thing that keeps it switched on so you can work the suspension for a

bit after turning off the ignition) would be in the socket with the blue blob

on it but this picture is the old ECU in messed up head mode so the relay was

out to keep some scuba air in the suspension.

The PCB is inverted when it is installed but putting a USB connector through

the side of the case near the front on the outside seemed a natural test,

diagnostic and reprogramming adaptation. Remember that there is still a fault

with my air suspension, one that drives the CPU mad, so when this is all

working I need sensible problem reports so I can fix that. Odds on a bad

connection somewhere anybody?

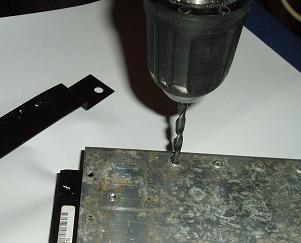

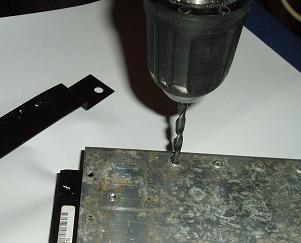

First I trimmed the metalwork to get room for the USB connector. Sadly I can't

punch the USB socket into the PCB as I will never get the metalwork off again

so it will have another mounting method. Then the rivet holes were drilled out

and cinche nuts pressed in. M4 was perhaps a bit over generous here as in one

hole the drill carried away all the metal so I'm a bolt short of ideal but it's

not near anything that needs heat sinking an there were spare holes anyway so

it doesn't need the screw to damp-proof it.

First I trimmed the metalwork to get room for the USB connector. Sadly I can't

punch the USB socket into the PCB as I will never get the metalwork off again

so it will have another mounting method. Then the rivet holes were drilled out

and cinche nuts pressed in. M4 was perhaps a bit over generous here as in one

hole the drill carried away all the metal so I'm a bolt short of ideal but it's

not near anything that needs heat sinking an there were spare holes anyway so

it doesn't need the screw to damp-proof it.

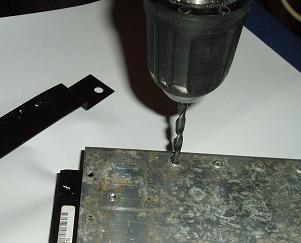

The key trick is to make and mount the PCB so it will survive the kind of off

road experience that was one of the reasons for buying a Range Rover in the

first place. I located two points on the board that I feel I could safely drill

a hole and put a pillar into and drilled it 3mm. To fit a 2x3 inch PCB over

that are I only need 7mm of clearance. (Sorry I keep unit switching but PCBs

are still in my mind as designed on the one tenth of an inch grid as that's how

all our components come so we work in inches while our fastenings are all

metric. We dive mechanical engineers nuts.) The PCB wants to be of ground-plane

type construction as that makes for nice stable CPUs once you start clocking in

the tens of MHz and above region.

The total height I have to play with is 21mm so with 8mm spacing, 1mm for the

PCB thickness I still have 12mm before I bump the case. This means I can have

test connectors and indicators on the prototype board - not that there will

ever need to be another but, hey, I make production quantity product, I think

that way.

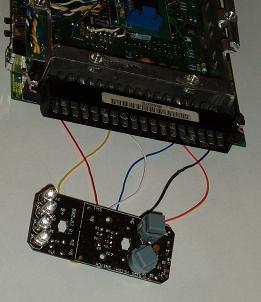

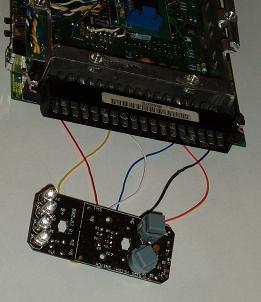

Right now, here are the new PCBs with the new CPU and the USB socket.

Right now, here are the new PCBs with the new CPU and the USB socket.

I must be smug and say that Combro do do a nice PCB. The surface mount LEDs

are a nice touch. You can't see them? True. They are green and you don't see

them until they light up.

I must be smug and say that Combro do do a nice PCB. The surface mount LEDs

are a nice touch. You can't see them? True. They are green and you don't see

them until they light up.

The only snag is that although my brother is a wizz on the CAD system the other

brother in the partnership missed one critical dimension on the small board and

got a couple of net labels wrong on the other. Still once it was mounted the

ghastly botch with a hacksaw barely showed.

It needed a lot of work before it was ready to boogie though but standing on a

couple of M3 bolts it looks quite neat. I must confess it is less tidy

underneath. There are 32 wires connecting the new CPU card to the PCB beneath

and I started wiring in nice heat-proof hook-up wire but as the quantity

of cable grew I got nervous about how the board would ever fit with all that

underneath it so I shifted to some thinner stuff but with a slight tendency to

shrivel away from the soldering iron. However it's all done and I'd rather have

flexible cables in a car application.

I can't finish this section without a shot of it hooked up to the remains of

that ride-height switch I bought. OK the program I was running at the time was

just "read the switches" "write the lights" but it was nice to see something

working after all this time.

I can't finish this section without a shot of it hooked up to the remains of

that ride-height switch I bought. OK the program I was running at the time was

just "read the switches" "write the lights" but it was nice to see something

working after all this time.

Well this was the point where I thought it would all be plain sailing and the

software would be the easy bit. OK I'd had some problems with the programming

jig but when I discovered that the problem was pin loading adding a secondary

socket between the programmer and the chip with all the pins cut off except for

the ones I needed sorted that. There is something very funny about writing

to port A on these PICs but that is probably because I have it smeared over

the Analogue to Digital converter pins. Also it was a bit of a head banger

getting the USB going but there was more fun to come on that score.

Once I got over the elation of real lights changing to button presses I noticed

that when I pulled out the USB cable everything stopped. This was worrying as

permanently plugging in the lap top when I want to drive was not in the game

plan. However I started to dig.

A quick poke with the 'scope showed the oscillator stopping as the cable came

out and, since it picked up again from where it left off when you put the cable

back, that had to be 'SLEEP' mode. A delve into the standard library from the

chip maker showed it just happened to have helpful code to kill the CPU into

power-saving mode when you pulled out the cable. A quick mod to the library and

the oscillator kept running.... pity nothing else did. Now digging into the

other parts of the library turned up code that loops to give the USB system the

benefit of the whole CPU when it is in disconnected mode. Another library frig,

and this one has to be a bit more wary as this code overlaps projects we are

selling, so no bugs here. Finally the lights flash and move without the

USB.

OK so it's 9.30 at night and wet as can be but this is going in the car with

null software to see if it drives the switch there AND does it get rid of the

SLOW:35 MPH MAX message? To cut a long story

short it does. It did flash a 20MPH MAX message at me a couple of times but

mostly everything was OK. Nothing turned on, so I have all the right

initialisation values, and the dimly remembered RANGE and MPG displays showed

up. Went to bed a happy bunny.

The next couple of days involved sorting out the Analogue to Digital

converters, discovering that the 'Engine RPM' signal was, as suspected, spark

rate so an easy conversion, checking the outputs really did output and

improving the program that ran on the PC to keep track of all the data I could

generate. With that done real numbers were being obtained so I was ready to

move. forwards to actually controlling something.

The first trials worked but weren't all that exciting but I now had suspension

again.

The next CPU problem was the Microchip boot-loader. The problem was that it is

designed to flash lights to tell the programmer what his program is doing but

just to reassure the rest of us that things are working. However the two lines

it wants to use are two of my solenoids and I don't want to flash them.

Originally I though I could just disconnect while program loading and I had

arranged for the CPU to power from the USB to make this happen but this was

beginning to get tiresome. The answer was to identify the program instructions

that drive the lights from the supplied listing and hit them with a binary

editor to NOPs...

So if anybody else needs a Microchip variant bootloader tested on a 18F4550

that does not even initialise the PORTE LED bits here it is

nig-boot.hex.

It still obeys PORTB bit 5 low to go into boot mode but to change that would be

a one location hit.

Now at least I just need to push one button while holding the other down and

I'm in program load mode.

More on the Ride Height Switch lights

More on the Ride Height Switch lights

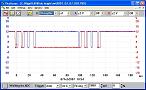

I got the 'scope on the system

and made a basic analysis of what was coming out and, since I had already

dissected a switch, the protocol was simpler than I expected. The plot shows a

normal display of the third light up lit. Click the thumbnail for a

readable image.

The clock line, the blue trace, stays high (12V) most of the time but since the

board inverts both signals that is a logic '0' out from my CPU. It goes low for

2mS and is then high for 8mS between pulses. The pattern repeats every 100mS.

The data line (blue trace) is clocked into the switch's display shift register

by the rising edge of the clock so if it is required to be low it sets low with

the clock and sets high again 2mS after the clock. Between the 100mS frames the

data line alternates between high and low and this probably supplies a

simplistic I am alive signal to the BECM without the CPU there having to

actually read the data. If you look at the plot you can see the rising edges of

the blue line match up with the red being low, low, high, low in both cases.

This sets the lights in ascending order. This is reasonably trivial to program.

I have a 1mS heart-beat as my basic timer so I will just service the data lines

every 2mS and cycle in 200mS to cater for the alternating state of data in the

gap.

I started to cut the picture of my simulation but realised that was silly. You

can't tell them apart. The only snag with testing indoors is that you need to

add pull up resistors to the test jig, I used 5K6 to 12V, because the EAS ECU

only pulls down.

Incidentally... If I set the line high in both gaps rather than alternating the

BeCM displayed the 35MPH warning message and if I set it

low it showed EAS Manual.

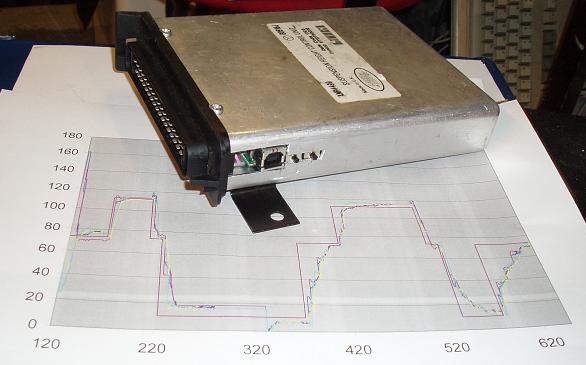

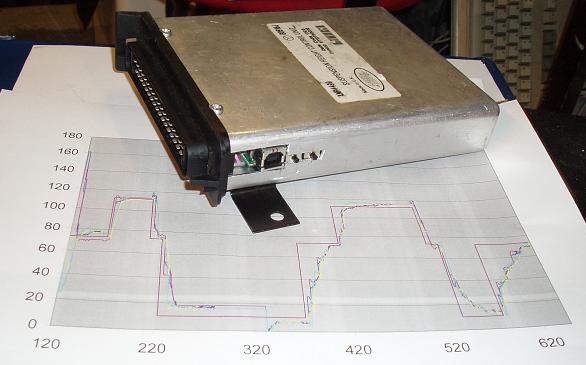

The first version ran

reasonably. The plot is a test run - time in seconds and height in mm. It was a

bit slow but it followed the demanded height quite well.

The first version ran

reasonably. The plot is a test run - time in seconds and height in mm. It was a

bit slow but it followed the demanded height quite well.

It didn't do things like always lift the back first yet as it just trimmed

round to taper into the required height and it was having trouble talking to

the BeCM even though the ride-height switch on the same circuit was quite happy

as this was before I got my ECU reset and 'scoped its outputs (see above). It

did, however, allow me to dump out values and begin to see a pattern where it

would drive high. Remember I am still hunting for the elusive fault that drives

EAS ECUs mad and I begin to suspect a wiring problem in the sensors.

Revise that: a wiring problem to the rear-right solenoid. It was now pretty

predictable. The rear-right wheel didn't respond. That is a killer to the

standard box but not to mine. Rattle the cables on plug C152 and most times it

comes back. Now the valve gear has been changed twice so the plug itself is

worth looking at. So I put it into the shop for a new plug, specifically a nice

new set of crimps. Watch this space - as they say...

Well that didn't seem to fix it but it's still intermittent and rattling the

cables on C152 makes it come and go. I was frustrated and just put up with it

for a while. What-ever the problem was it now failed first thing but once the

whole system had warmed up it worked so it wasn't too bad now I had a box that

didn't need resetting all the time.

So what next? I tried

putting a bridge wire from the harness to bypass the whole C152 section but

that worked for a few weeks then the fault came back. It does seem that

disturbing the wiring improves things which, I suppose, is why the garage can

always 'fix' it. It just doesn't stay fixed and I really want it to stay

fixed.

So I delved again with a voltmeter on the wire and jiggling things about. The

connection seemed good and yet the valve was not pulling in so it was time to

take the whole box apart, something I'd rather been putting of until then. I

got out the camera again so I had a record of how it was to go back together

again (they are big files so don't bother unless you really need them).

Sadly, by the time I've got it on the bench the intermittent fault is not showing

but I am somewhat surprised to discover that the valve block may be dated 2004

but the electronics package is dated 1984 and, frankly, looks it. I wiggle the

wires and I think I got a momentary break on the right one but it's impossible

to be sure but I decided to change it anyway. I Googled the part number and

www.p38spares.co.uk came up and they had one in stock at £170 so I

ordered it and fitted it.

So what happened? I wasn't sure at first but it seemed to be working and after

most of a holiday away I swapped back onto the original computer to see if it

would stay going. Well so far it has.

So what happened? I wasn't sure at first but it seemed to be working and after

most of a holiday away I swapped back onto the original computer to see if it

would stay going. Well so far it has.

If it does turn out to be this I will be annoyed. The garage have removed this

lump twice to fit a new valve block. If you're going to do an expensive job and

then redo under warrantee it some checks might have been in order. I don't

know. I expect there are lots of good excuses but it doesn't do much for my

opinion of garage men. Like the twerp who has been cutting back and refitting

the perished end of my cruse control vacuum pipe for it to only last a

fortnight before it goes again. It may yet fail but it's still going a month or

more later and lots of miles. I'm taking it down to Geneva and back soon so it

it does that without a tremble I'm going to count it as a done job.

After another four weeks I refitted the cover on the boxes under the passenger

seat. How's that for confidence?

So what else?

Well things all trundled along for a while with the usual EAS grumbles but then

it started developing a 'leaky bag' symptom. So I sigh a big sigh and bung it

in the shop for a fix.

Well they fixed the worn front disks. They fixed the corroded rear brake pipes.

They fixed the worn anti-roll bar rubbers but, despite having it for three days

all they could say was that they couldn't get their computer to talk to the EAS

computer. By now the bill was getting into 4 digits so I brought it home and

promised myself I'd fix it.

The problem was that I didn't really have 'nice' control of the system with my

current system. The on-board program had only been developed as far as it

needed to go to keep things running. I wanted a proper 'car simulation' to plug

it into at my desk so I could do the job simply.

The problem was that I didn't really have 'nice' control of the system with my

current system. The on-board program had only been developed as far as it

needed to go to keep things running. I wanted a proper 'car simulation' to plug

it into at my desk so I could do the job simply.

So, out came the soldering iron and this is what I made.

So, out came the soldering iron and this is what I made.

I used a real up/down controller from Ebay to 'prove' it worked but the rest of

the switched inputs are simple switches, the outputs are LEDs, the strut

variable resistors are normal 'volume control' style components with knobs and

the MPH and RPM pulse trains are generated by small oscilators. The engine

speed is a simple on/off while the road speed has an off state and two speeds

so I can see the ride hight change. The whole thing is powered by a 12 volt

power supply out of the junk box that used to power some gadget years

ago.

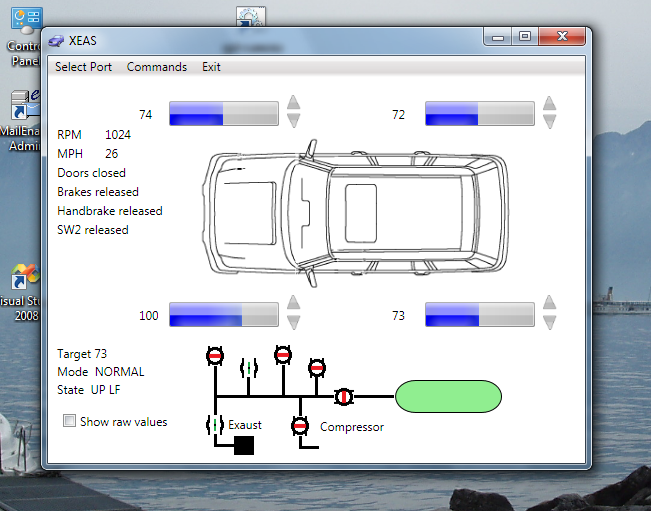

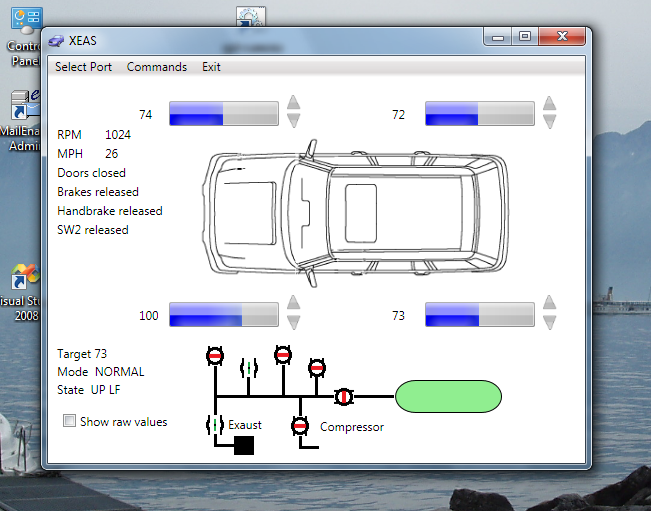

Since my EAS box is USB controlled I also took the opportunity to upgrade the

original simplistic software so something that would give me more intuitive

control. It is written in WPF and is seen here running on Windows 7. I managed

to catch it with the screen grab when it reports the 'exhaust' and 'rear right'

valves open. If the 'Inhibit' switch is closed (ie the push button on the

Rangie dashboard next to the Up/Down selector the controller shuts all the

valves and waits for instructions. Clicking a valve toggles it between open and

closed while click-and-hold on the big up/down arrows next to the blue strut

height graphics open both the strut valve and the appropriate exhaust or

inlet valve and releasing the mouse closes them both again.

Since my EAS box is USB controlled I also took the opportunity to upgrade the

original simplistic software so something that would give me more intuitive

control. It is written in WPF and is seen here running on Windows 7. I managed

to catch it with the screen grab when it reports the 'exhaust' and 'rear right'

valves open. If the 'Inhibit' switch is closed (ie the push button on the

Rangie dashboard next to the Up/Down selector the controller shuts all the

valves and waits for instructions. Clicking a valve toggles it between open and

closed while click-and-hold on the big up/down arrows next to the blue strut

height graphics open both the strut valve and the appropriate exhaust or

inlet valve and releasing the mouse closes them both again.

AND FINALLY...

People keep asking for the source code and I usually warn them that the device

was never finished beyond the point where it allowed me to diagnose the problem

with the 'real' system so it won't be much use to them. However the the

requests keep coming so so I release it.

Usual GNU terms apply. This is UNSUPPORTED code that I wrote quite a long time

ago now and I am NOT answering questions on it because I don't remember any

details. It doesn't work well because it was only ever just a test

framework.

CPU code using the FED compiler (which I would NOT recomend)

XEAS Windows display module for VS2008

One last note: in 2017 the poor thing threw its MOT test like a ton of bricks

with a list of advisories to make you weep. It also had a bunch of other faults

I was 'saving' for after the MOT and when several required parts came up 'no

longer available' it just had to go the way of all things that have become more

expensive than their value. It went to a farm and probably was cannibalised to

keep two of its fellows working but I like to think of them sitting in a barn,

chatting about the good times. It was frustrating at times but fun. Rust in

peace.

by Nigel Hewitt

by Nigel Hewitt

Range Rover P38 Electronic Air Suspension

Range Rover P38 Electronic Air Suspension

OK. I admit it. After two and a half years of messing about with the Air

Suspension on my 1996 Range Rover 4.6 HSE I had had a serious sense of humour

failure. I can't complain about the main agent as they had long since

ceased to charge me for the work on the EAS but even plaintive phone calls from

them to the factory was just resulting in bits being changed and no fix that

lasted.

OK. I admit it. After two and a half years of messing about with the Air

Suspension on my 1996 Range Rover 4.6 HSE I had had a serious sense of humour

failure. I can't complain about the main agent as they had long since

ceased to charge me for the work on the EAS but even plaintive phone calls from

them to the factory was just resulting in bits being changed and no fix that

lasted. I purchased a kit on EBay to fit T-connectors into the air suspension lines so

you could blow them up manually. Now I suspect that when people are selling

kits to fix a fault the problem is widespread so I am more surprised there

wasn't a factory fix. Anyhow with the kit fitted, a handy scuba cylinder of

compressed air in the boot and a scuba drysuit feed stuffed in a cheap garage

air filler I could pull the power relay, manually blow the system back up

and get home at 70mph like a civilised person. I had to do this from North

Wales once and I did a trip to Falmouth and back towing a 6.5 meter dive club

boat entirely on scuba power.

I purchased a kit on EBay to fit T-connectors into the air suspension lines so

you could blow them up manually. Now I suspect that when people are selling

kits to fix a fault the problem is widespread so I am more surprised there

wasn't a factory fix. Anyhow with the kit fitted, a handy scuba cylinder of

compressed air in the boot and a scuba drysuit feed stuffed in a cheap garage

air filler I could pull the power relay, manually blow the system back up

and get home at 70mph like a civilised person. I had to do this from North

Wales once and I did a trip to Falmouth and back towing a 6.5 meter dive club

boat entirely on scuba power.

OK. I won't bore you with the internal details of the circuit of the EAS ECU

mainly because I can't be bothered to redraw my scrappy sketches onto the cad

system but here is the pin out for the connector on the

ECU. I traced the circuitry and mapped the signals onto the PCB which gave

me the connection points by name. All the logic

signals are referenced down for a CPU running on 5 volts and the analogue

inputs are buffered and amplified similarly. Nothing is muxed. Nothing seems to

require special handling except the Ride Height Switch.

OK. I won't bore you with the internal details of the circuit of the EAS ECU

mainly because I can't be bothered to redraw my scrappy sketches onto the cad

system but here is the pin out for the connector on the

ECU. I traced the circuitry and mapped the signals onto the PCB which gave

me the connection points by name. All the logic

signals are referenced down for a CPU running on 5 volts and the analogue

inputs are buffered and amplified similarly. Nothing is muxed. Nothing seems to

require special handling except the Ride Height Switch. Right now this wants fitting to the 18F4550 CPU with the minimum of fuss.

Right now this wants fitting to the 18F4550 CPU with the minimum of fuss. Right so the next

problem is to reconstruct it so it can be reinstalled and maintained. In my

book this does not involve pop-rivets.

Right so the next

problem is to reconstruct it so it can be reinstalled and maintained. In my

book this does not involve pop-rivets. First I trimmed the metalwork to get room for the USB connector. Sadly I can't

punch the USB socket into the PCB as I will never get the metalwork off again

so it will have another mounting method. Then the rivet holes were drilled out

and cinche nuts pressed in. M4 was perhaps a bit over generous here as in one

hole the drill carried away all the metal so I'm a bolt short of ideal but it's

not near anything that needs heat sinking an there were spare holes anyway so

it doesn't need the screw to damp-proof it.

First I trimmed the metalwork to get room for the USB connector. Sadly I can't

punch the USB socket into the PCB as I will never get the metalwork off again

so it will have another mounting method. Then the rivet holes were drilled out

and cinche nuts pressed in. M4 was perhaps a bit over generous here as in one

hole the drill carried away all the metal so I'm a bolt short of ideal but it's

not near anything that needs heat sinking an there were spare holes anyway so

it doesn't need the screw to damp-proof it. Right now, here are the new PCBs with the new CPU and the USB socket.

Right now, here are the new PCBs with the new CPU and the USB socket. I must be smug and say that Combro do do a nice PCB. The surface mount LEDs

are a nice touch. You can't see them? True. They are green and you don't see

them until they light up.

I must be smug and say that Combro do do a nice PCB. The surface mount LEDs

are a nice touch. You can't see them? True. They are green and you don't see

them until they light up. I can't finish this section without a shot of it hooked up to the remains of

that ride-height switch I bought. OK the program I was running at the time was

just "read the switches" "write the lights" but it was nice to see something

working after all this time.

I can't finish this section without a shot of it hooked up to the remains of

that ride-height switch I bought. OK the program I was running at the time was

just "read the switches" "write the lights" but it was nice to see something

working after all this time. More on the Ride Height Switch lights

More on the Ride Height Switch lights The first version ran

reasonably. The plot is a test run - time in seconds and height in mm. It was a

bit slow but it followed the demanded height quite well.

The first version ran

reasonably. The plot is a test run - time in seconds and height in mm. It was a

bit slow but it followed the demanded height quite well. So what happened? I wasn't sure at first but it seemed to be working and after

most of a holiday away I swapped back onto the original computer to see if it

would stay going. Well so far it has.

So what happened? I wasn't sure at first but it seemed to be working and after

most of a holiday away I swapped back onto the original computer to see if it

would stay going. Well so far it has. The problem was that I didn't really have 'nice' control of the system with my

current system. The on-board program had only been developed as far as it

needed to go to keep things running. I wanted a proper 'car simulation' to plug

it into at my desk so I could do the job simply.

The problem was that I didn't really have 'nice' control of the system with my

current system. The on-board program had only been developed as far as it

needed to go to keep things running. I wanted a proper 'car simulation' to plug

it into at my desk so I could do the job simply. So, out came the soldering iron and this is what I made.

So, out came the soldering iron and this is what I made. Since my EAS box is USB controlled I also took the opportunity to upgrade the

original simplistic software so something that would give me more intuitive

control. It is written in WPF and is seen here running on Windows 7. I managed

to catch it with the screen grab when it reports the 'exhaust' and 'rear right'

valves open. If the 'Inhibit' switch is closed (ie the push button on the

Rangie dashboard next to the Up/Down selector the controller shuts all the

valves and waits for instructions. Clicking a valve toggles it between open and

closed while click-and-hold on the big up/down arrows next to the blue strut

height graphics open both the strut valve and the appropriate exhaust or

inlet valve and releasing the mouse closes them both again.

Since my EAS box is USB controlled I also took the opportunity to upgrade the

original simplistic software so something that would give me more intuitive

control. It is written in WPF and is seen here running on Windows 7. I managed

to catch it with the screen grab when it reports the 'exhaust' and 'rear right'

valves open. If the 'Inhibit' switch is closed (ie the push button on the

Rangie dashboard next to the Up/Down selector the controller shuts all the

valves and waits for instructions. Clicking a valve toggles it between open and

closed while click-and-hold on the big up/down arrows next to the blue strut

height graphics open both the strut valve and the appropriate exhaust or

inlet valve and releasing the mouse closes them both again.

by Nigel Hewitt

by Nigel Hewitt